About Client

A global leader in the printing industry transformed their customers’ printing equipment CapEx problem to an OpEx one, by offering ‘Print as a Service’ solution. This business innovation helped the end customer to focus on their core business instead of printing issues.

Business Need

- A proactive approach towards maintenance of large print equipment and replacing the existing reactive approach that responds to customer complaints.

- Offer predictive maintenance that reduces the overall cost of ownership and maintenance of the printing equipment.

Challenges

- Paper based manual process. Maintenance and service schedules were paper-based for a huge network of equipment.Incomplete data capture of the service activities leading to low level analytics.

- Digitization with huge manuals.

Digital transformation had to integrate with physical equipment service tools, parts, and volumes of task instruction manuals.

Our Solution

True digital transformation – The Maintenance Manager 4.0 was developed as an automated solution for tracking and monitoring equipment maintenance.

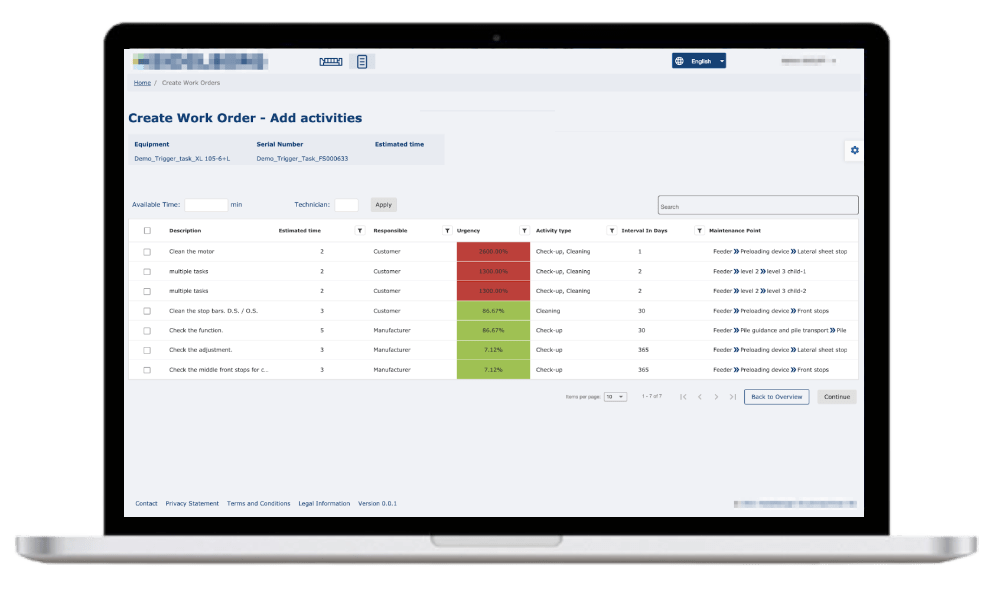

A web interface was designed that contained the database of all the equipment with their respective maintenance priorities. The maintenance managers could create work orders based on the maintenance urgency of the equipment and assign them to technicians. All maintenance instructions were made available digitally.

Smarter Maintenance – A mobile interface notified the technicians of their work orders that provided detailed maintenance instructions. It also allowed them to update task completion, and other relevant data. The service instructions specific to the equipment parts were available in the mobile interface, doing away with the time-consuming search for instructions from heavy manuals.

Task to be performed on

a machine

Pre-maintenance check

Business Impact

- True digital transformation integrating all the activities related to equipment maintenance.

- Customer centric approach driving business strategy – the equipment downtime is almost eliminated with systematic preventive maintenance schedules.

- Saved time translating to greater ROI – the technician knows exactly what is to be done and the parts needed for the task are readily available digitally.

- Visibility to the stakeholders on the maintenance efforts.

- Complete data on the health of the equipment.

- Availability of all maintenance data including images where applicable, enables predicting the life of the equipment and aids in a strategy for end-of-life planning of the equipment.

Technology

Tech Prescient was very easy to work with and was always proactive in their response.

The team was technically capable, well-rounded, nimble, and agile. They had a very positive attitude to deliver and could interpret, adopt and implement the required changes quickly.

Amit and his team at Tech Prescient have been a fantastic partner to Measured.

We have been working with Tech Prescient for over three years now and they have aligned to our in-house India development efforts in a complementary way to accelerate our product road map. Amit and his team are a valuable partner to Measured and we are lucky to have them alongside us.

We were lucky to have Amit and his team at Tech Prescient build CeeTOC platform from grounds-up.

Having worked with several other services companies in the past, the difference was stark and evident. The team was able to meaningfully collaborate with us during all the phases and deliver a flawless platform which we could confidently take to our customers.

We have been extremely fortunate to work closely with Amit and his team at Tech Prescient.

The team will do whatever it takes to get the job done and still deliver a solid product with utmost attention to details. The team’s technical competence on the technology stack and the ability to execute are truly commendable.